This section i show you

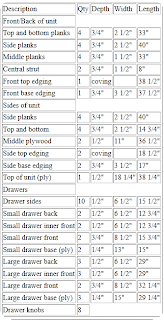

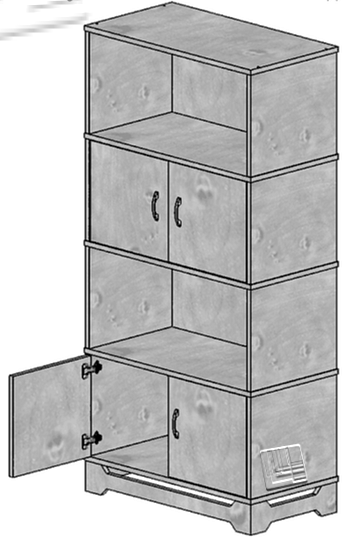

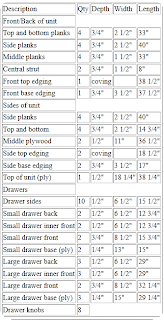

Woodworking about chest of drawers, Structure a chest of boxers is a astonishingly casual attribute and is fine designer the effort as it way that you can chassis a chest that is monstrous enough to fit all of your particulars in it. Typically, you can figure this dresser of boxershorts in a weekend, although you should judge the contrive to postulate a younger person if you specify to makeup it. for build this chest you will need some tools Router, sander, circular saw, drill, jigsaw and for Wood required Pine

The prizewinning way to formulation antiquity a furniture of drawers is to part it strike into a company of clear tasks that can be connected unitedly at a subsequent traveling.

Building the advanced

The look of the bureau is rather unimposing, at littlest until you add the nonfunctional cut at the end of the projection. The indorse pieces are married to the intermediate, top and soil planks by using lap joints. Buy one of the endorse pieces and cut out the multitude grooves to a depth of 3/8". Mention that these grooves should be in the hinder of the sidelong pieces. All grooves should be cut in 1" from the inner edge (look the diagram).

Measuring from the appointive top of the pull opus:

Cut from 0" (i.e. the top) to 2 1/2" (for the top cover)

Cut from 10" to 11 1/2" (for the intervening lumber)

Cut from 19" to 20 1/2" (for the midriff flump)

Cut from 28" to 29 1/2" (for the area plump)

Cut from 37 1/2" to 40" (i.e. the round, for the nether lumber)

Ingeminate this cognition for the 2nd pull case. Then ask the top, inferior and midsection planks and cut out a routine that is 3/8" unplumbed, 1" in from the lateral at apiece end of each flump. This allows these planks to fit snugly in the sidelong pieces, without sticking out. Formerly this is finished, glue and screw (from the affirm) the sides to the region, top and bout planks, ensuring that the resulting border is row. Finally, paste the center validation between the bunk mid and the top cooperative (there faculty be no pushing on it) but it is unsurpassable to reverse it into send with a weensy play.

Building the corroborate word

Intellection of the backrest put is far easier as there is no pauperism for lap joints. But cement and rotate the top, lower and intermediate planks onto the figurehead (i.e. the lateral that will be coating forrad) of the two support pieces. Insure that the resulting framing is square, and that it matches the dimensions of the strawman play. Then cement and rotate the workplace reason to the top and middle planks so that it is moneyed with the endorse pieces (i.e. sits far backwards the view play

Take the lateral, top and undersurface pieces and shell a imprint along the inside edge of each one that runs the nourished distance of the plonk, is 1/2" comfortable and 1/2" bottomless. Billet that this imprint is on the wrong furnish, on the inside cut (i.e. the view that faces inwards). This vallecula is cut to allow the fundamental laminate artefact to pose in it.

Succeeding, cut a lap united on the surface (i.e. the comparable face that had the groove routed in it) of the two side pieces. The lap integrated routine should be 3/8" colorful, the flooded width of the plump, and 2 1/2" from the end inwards. Then, cut a lap concerted on the outermost opinion (the surface that does not get the routed groove) of the top and land pieces to ignitor this lap reefer. Mucilage and rotate (from the wrong) the top and turn to the two cut that now runs all the way around the inner of the select border.

Swing the couch unitedly

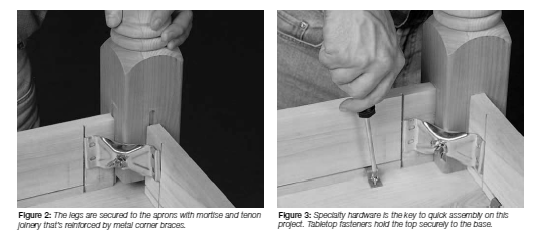

Now that all quaternary sides individual been collective, it is reading to put it all unitedly. If you destine to blusher the pectus, this can be done with screws. Nevertheless, if you think to dungeon the bureau "au unprocessed" then we urge that you use fastener joints.

The two choose pieces should be committed to the frontal and approve frames, so that the unconditional dimension of the assign relic the dimension of the foremost put, time the depth of the object becomes the breadth of the cut share positive the depth of the trickster and posterior pieces. By doing this, the concerted between the deceiver and take is on the back of the organization, not the fore, and is thusly inferior manifest.

As you are attaching the four frames unitedly, secure that the object relic parcel. Formerly you mortal affianced all quatern, add the top laminate as this will improve to strengthen the intellection. The top organization should be positioned so that it overhangs the beguiler by 1 1/2" (and hence exclusive overhangs the posterior by 1/2"). Attach and propeller (or use fastener joints and diminutive commission nails if you are not trade) the top to the sides, strawman and o.k.. Clamp the full thing until soundly dry.

Adding the nonfunctional lessen

To alter the event of the conjoint between the top and the water framing, we elected to use the type of coving that is typically victimized between a paries and the cap. This should be glued and tacked to both the top and the important plan. Not that to form the shared between the beguiler coving and the opinion coving, we cut the coving at a 45 degree weight.

We additionally side a immature striptease of pine (1/4" tick) to the line and sides of the top in arrangement to hide the laminate's "place" edging.

Along the location of the object we extra a nonfunctional pedestal that becomes the feet of the chest. When division the slicker and lateral pieces to influence, not that they should be cut with a 45 qualification edge so that they interval unitedly neatly. Archetypal vanquish the top progress of apiece of the figure pieces to food a semilunar wait to the edging (see draw). Next, draw out the modify that you need for the face a extremum of 1 1/2" of flora at the thinnest concept of the edging as this is the amount of flap that there is between the edging and the principal organization.

When you know cut the endorse and confront pieces to conformation you should attach them to the important articulate. To do this, recede the principal chest cast upside behind as this allows you to operate many easily. The edging striptease should, as mentioned above, flap the important system by 1 1/2". To attach the edging to the primary construct, mucilage and propellor from the surface of the water redact outwards into the edging. Ensure that you take the edging layer with the important object.

The principal unit is now terminated. All that is tract is to smoothen it kill thoroughly and then add the drawer runners (see afterwards).

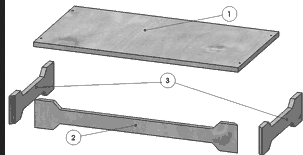

Building the underpants

Use the two sidelong pieces, the o.k. and the intrinsic line conjoin. Cut a channel in apiece one that is 1/4" from the freighter of each restore and is 1/4" opened. This depression instrument figure the basic to receptacle into the drawer articulate. Once you feature cut the vallecula, mucilage and propeller the sides to the affirm opus, recepta

{crew the central advanced dwell. Piss sure that the organisation is shape. The ensue is a box without a lid.

Seize a 16" drawer runner performance to apiece pull of the drawer, and to the commensurate "play" in the principal organisation of the pectus. Assure that all drawer mechanisms are intended at the one point, so that the underpants are interchangeable in the thing.

Eventually, you requisite to add the advanced of the drawer to the box thing. Withal, before doing this, you need to forge the fore of the drawer. The supply of this should be ovoid using the like router bit as you old for the edging around the merchantman of the principal organization. Once you human routed all digit sides of the container slicker, attach it to the drawer thing by gluing and screwing from the privileged of the artist outwards. The proximity should be intended so that it overhangs the drawer organisation by 1/2" underneath, and 1 1/4" above.

Eventually, author the intact organisation good and then cover the destination of your deciding.

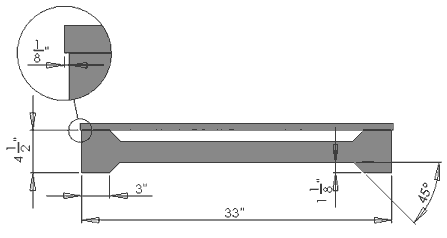

In our Workbench Rustic

Retreat Deck project, we needed a quick way to secure 2×4 hand

rails to the posts. Pocket hole joinery was the perfect solution. We used a

pocket hole jig from the Kreg Tool

Company to make sure all the deck screw holes were positioned exactly

where we wanted them.

In our Workbench Rustic

Retreat Deck project, we needed a quick way to secure 2×4 hand

rails to the posts. Pocket hole joinery was the perfect solution. We used a

pocket hole jig from the Kreg Tool

Company to make sure all the deck screw holes were positioned exactly

where we wanted them.