We meet again here now we share for build

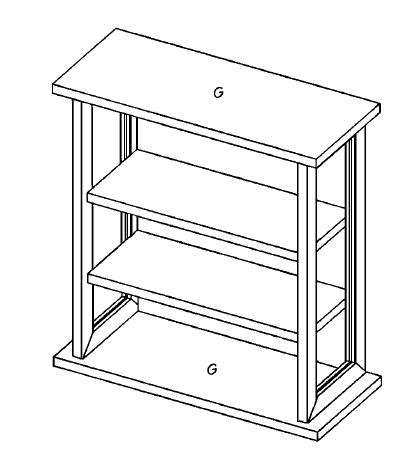

Armoire Two door Plans Woodworking No concern e'er has sufficiency storage set, and I improved this armoire to fulfill a couple of

needs. Privileged the armoire is a ridge huge enough for the telecasting. Under the shelf are six

underpants that make a tracheophyte of family muddle. (Did I say "muddle"? What I truly meant was

"treasures"--right, that's it--family treasures!)

The classy quality of this serving belies its unhurried artefact.

Although there are a identify of

steps to rise, apiece can be established without any innovative woodworking skills. To urinate an

armoire you'll be gratifying to conduct your friends, you requisite exclusive move your abstraction, coordinate the doors and

drawers utterly, and fit the beautify border carefully. No one will hypothesis that you exclusive utilised the

simplest expression techniques.

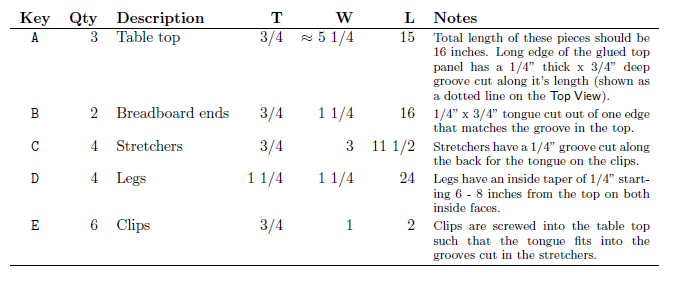

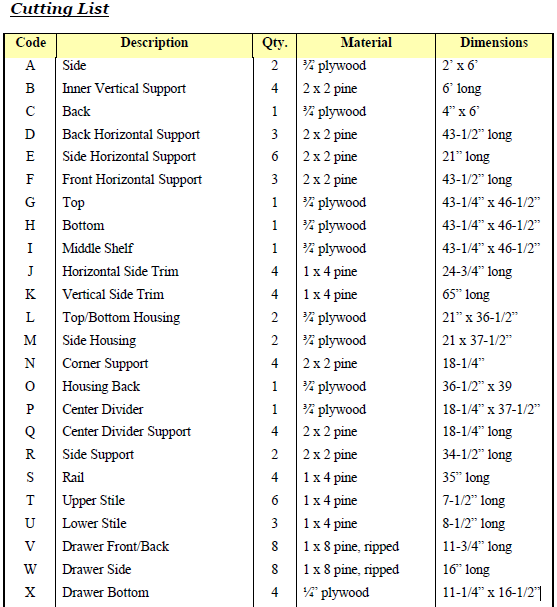

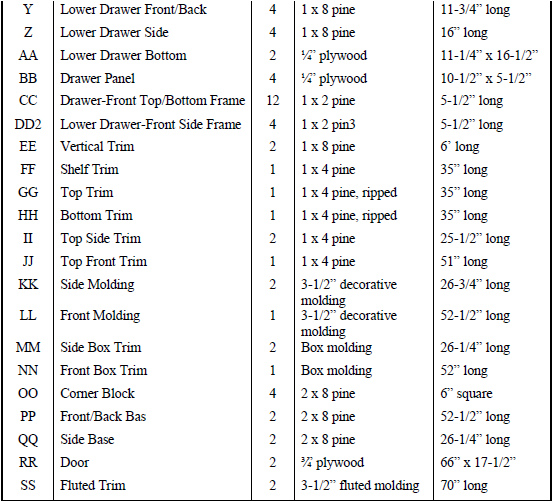

this is what you will need for buil

simple woodworking Armoire Two door :

Materials

§ 18 linear feet of 1 x 2 pine

§ 74 linear feet of 2 x 2 pine

§ 66 linear feet of 1 x 4 pine

§ 42 linear feet of 1 x 8 pine

§ 16 linear feet of 2 x 8 pine

§ One 4’x 4’sheet of ¼”stain-grade plywood

§ 5 sheets of 4’ x 8’ ¾” stain-grade plywood

§ 9 linear feet of decorative molding, 3-1/2”wide

§ 9 linear feet of box molding

§ 28 linear feet of 1” x 1”outer corner molding

§ 12 linear feet of fluted moldings, 3-1/2” wide

§ 18 linear feet ¼” x ¼” cove molding

Hardware

· 6 offset door hinges

· 2 door levers

· 6 drawer pulls

· 2 lbs. #6 x 1-1/4”flathead wood screws

· 1 lb. #6 x 2” flathead wood screws

· 2 lbs. #6 x 2-1/4” flathead wood screws

· 2 lbs. #10 x 3-1/2” flathead wood screws

· Approx. 100 3d finishing nails

· 1 small box wire brads

Special Tools and Techniques for built it:

· Miters

· Dadoes

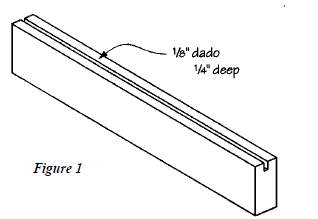

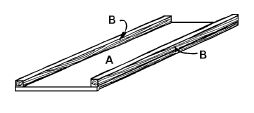

Constructing the Armoire Frame1. Cut two Sides (A) from ¾”-thick plywood, each measuring 2 x 6 feet.

2. Cut four Inner Vertical Supports (B) from 2 x 2 pine, each 6 feet long.

3. Attach two Inner Vertical Supports (B) to one Side (A) flush with both the 6-foot edges, as

shown in Figure 1. Use glue along the entire length, and 2-1/4-inch-long screws

approximately every six inches.

4. Repeat step 3 using the remaining Side (A) and the two remaining Inner Vertical Supports

(B).

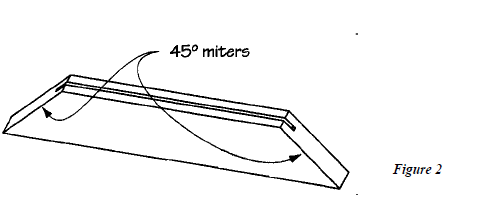

5. Cut one Back (C) from 3/4-inch-thick plywood, measuring 4 x 6 feet. Place it on a flat

surface and attach the two Sides (A) at right angles to the Back. Glue and screw the two

Inner Vertical Supports (B) to the Back (C) as shown in Figure 2. Again, use 2-1/4-inchlong

screws about every 6 inches.

Adding the Horizontal Supports

The armoire top, bottom, and the inner shelf are cut from ¾-inch-thick plywood, and are attached

to 2 x 2 pine horizontal supports inside the armoire frame. The horizontal supports fit between the Inner Vertical Supports (B) that you have already attached to the Back (C) and Sides (A). The back and side horizontal supports should be glued and screwed in place, using 2-1/4-inch-long screws placed approximately 6 inches apart.

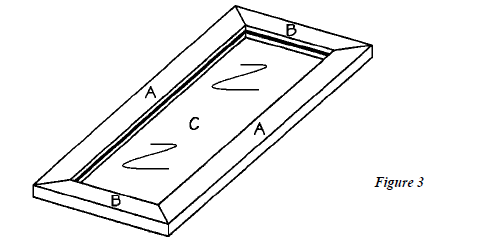

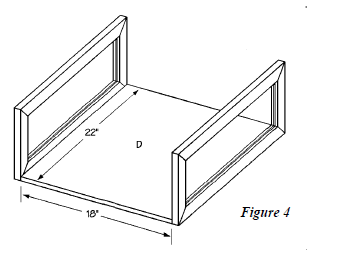

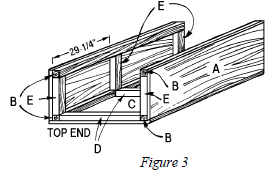

1. Cut three Back Horizontal Supports (D) from 2 x 2 pine, each 43-1/2 inches long.

2. Attach one Back Horizontal Support (D) between the Inner Vertical Supports (B) flush with

the exposed edge of the top of the Back (C), as shown in Figure 3.

3. Attach a second Horizontal Support (D) positioned between the two inner vertical supports

(B) and flush with the bottom edge of the back (C).

4. Measure 29 1/4 inches from what will be the top of the armoire, (it can be either end- -now is when you decide), and attach the remaining Back Horizontal Support (D) between the two Inner Vertical Supports, as shown in Figure 3.

5. Cut three Side Horizontal Supports (E) from 2 x 2 pine, each 21 inches long.

6. Attach one Side Horizontal Support (E) between the Inner Vertical Supports (B), flush with

the exposed top edge of the Sides (A), as shown in Figure 3.

7. Measure 29-1/4 inches from the top of the armoire, and attach the second Side Horizontal

Support (E) between the two Inner Vertical Supports (B), as shown in Figure 3.

8. Attach the remaining Side Horizontal Support (E) flush with the bottom exposed edge of

the Side (A).

9. Repeat Steps 5 through 8 to cut and attach three more Side Horizontal Supports (E) to the

remaining Side (A).

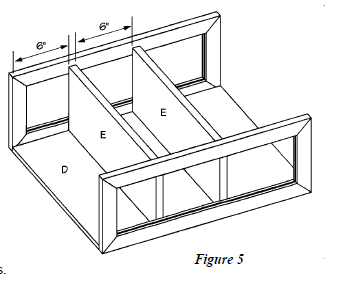

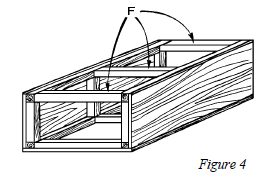

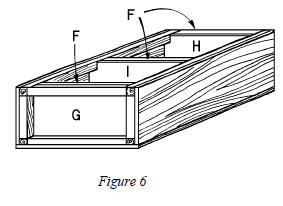

10. Cut three Front Horizontal Supports (F) from 2 x 2 pine, each 43-1/2 inches long.

11. Attach one Front Horizontal Support (F) between the Inner Vertical Supports, at the very top of the Sides (A). Use glue and 3-1/2-inch long screws, screwing through the Side (A), through the Inner Vertical Supports (B), and into the end of the Front Horizontal Support (F).

12. Attach the second Front Horizontal Support (F) between the Inner Vertical Supports (B), at the very bottom of the Sides (A).

13. Measure 29-1/4 inches from the top of the armoire sides, and attach the remaining Front Horizontal Support (F) between the Inner Vertical Supports (B). Again use glue and 3-1/2-inch long

screws.

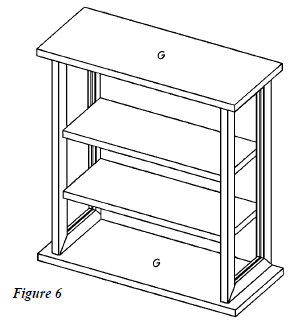

Adding the Top, Bottom, and Inner Shelf

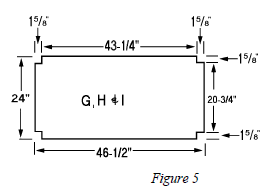

1. The Top (G), Bottom (H), and Middle Shelf (I) are identical. Cut each from ¾-inch-thick

plywood according to the diagram shown in Figure 5. Note that a 1-7/8-inch square must be

cut from each of the four corners to accommodate the Inner Vertical Supports (B).

2. Stand the armoire (well, half-assembled armoire) right side up. Fit the Bottom (H)

over the lowest inner 2 x 2 horizontal supports. Glue and screw it to all four of the horizontal supports using 1-1/4-inchlong screws. Take special care to make certain that the Front Horizontal

Supports are flush with the exposed edges of the Bottom (H) as shown in Figure 6. 3. Repeat the process to add the Middle Shelf (I) fitting it over the horizontal supports 29-1/4 inches from the top. Again make sure that the front edges are flush, as you did for the Bottom (H).

4. The Top (G) is attached to the uppermost horizontal supports, but is attached on the lower face of those supports, so the horizontal supports will not be visible inside the finished armoire. Attach it in the same manner used for the shelf (I), making sure that the front

edges are flush.

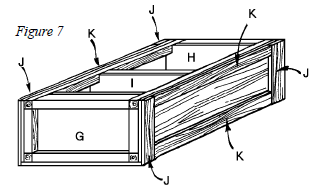

Adding the Side Trim

1. Cut two Horizontal Side Trim pieces (J) from 1 x 4 pine, each 24-3/4 inches long. Attach them to the two shorter ends of the Sides (A), overlapping the exposed edges of the Back (C), as shown in

Figure 7. Use both glue and 1-1/4”-long screws, countersinking the screws.

2. Cut two Vertical Side Trim pieces (K) from 1 x 4 pine, each 65 inches long. Glue and screw them along each of the 6-foot edges of the Sides (A), between the Horizontal Side Trim pieces (J) as shown in Figure 7. They also will cover the exposed edges of the Back (C).

3. Repeat Steps 1 and 2 to add Vertical and Horizontal Side Trim pieces (J and K) to the

remaining Side (A) of the armoire.

Building the Drawer Housing

The six interior drawers are housed in a plywood box that fits inside the lower portion of the armoire. The completed drawer housing measures 36-1/2 inches by 39 inches. Check the dimensions of your assembly at this point to confirm that the completed drawer housing will fit. It is better to adjust

the measurements of the drawer housing at this point than to discover that it is 1/8-inch too big when you attempt to fit it into the armoire.

Vertically, the drawer housing fits perfectly between the Front Horizontal Support underneath

the middle Shelf (I) and the Bottom (H), but is 7 inches less wide than the available horizontal

opening. The excess 3-1/2” of horizontal space on each side of the drawer housing is needed to

accommodate the 1 x 8 trim that you will add later to the front of the armoire. In total, 7-1/4

inches on each side will be covered by the trim.

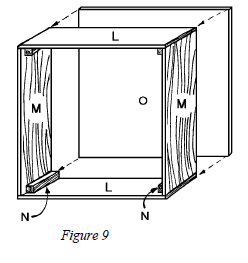

1. Cut two Top and Bottom Housing pieces (L) from 3/4-inch-thick plywood, each 21 x 36- 1/2 inches.

2. Cut two Side Housing pieces (M) from 3/4-inch-thick plywood each 21 x 37-1/2 inches.

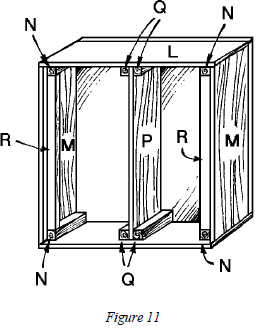

3. Cut four Corner Supports (N) from 2 x 2 pine, each 18-1/4 inches long.

4. Glue and screw two of the four Corner Supports (N) to the 21- inch edges of a Side Housing piece (M). Use 2”-long screws spaced about 6 inches apart. As shown in Figure 8, make sure that the Corner Supports (N) are flush with the back of the drawer housing, and 2-3/4-inches short of the front of the housing. This 2-3/4” spacing is necessary to accommodate the rails and stiles, which will be added later, and to allow space for the drawer fronts and drawer pulls when the armoire doors are closed over the drawer housing.

5. Glue and screw the remaining two Corner Supports (N) to the remaining Side Housing

piece (M) just as you did in Step 4.

6. Place the two Side Housing pieces (M) between the two Top and Bottom Housing pieces (L). Glue and screw the Top and Bottom Housing pieces (L) to the Corner Supports (N) at all four corners. You should now have a box measuring 36-1/2 inches wide and 39 inches tall (outside measurements) as shown in Figure 9.

7. Cut one 36-1/2” x 39” Housing Back (O) from 3/4-inch plywood.

8. Fit the Housing Back (O) over the exposed edges of the housing assembly and glue and screw it in place, as shown in Figure 9, using 1-1/4”-long screws.

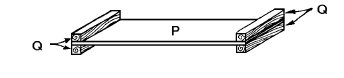

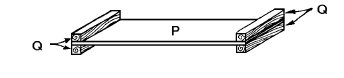

9. Cut one 18-1/4” x 37-1/2” Center Divider (P) from 3/4-inch-thick plywood.

10. Cut four Center Divider Supports (Q) from 2x 2 pine, each measuring 18-1/4” long.

11. With 2”-long screws, glue and screw all four Center Divider Supports (Q) to both sides of the Center Divider (P) along the 18-1/4-inch edges, as shown in Figure 10.

|

| Figure 10 |

12. Position the Center Divider (P) in the exact horizontal center of the drawer housing, flush against the Housing Back (O), as shown in Figure 11. Note that there will be a 2-3/4-inch allowance at the front of the drawer housing. Glue and screw the four Center Divider Supports to the Housing Bottom (L) and Housing Top (L). Using 2”-long screws, screw through the Housing Back (O) into the ends of the four Center Divider Supports (Q) and into the Center Divider (P).

13. Cut two Side Supports (R) from 2 x 2 pine, each measuring 34-1/2 inches.

14. Glue and screw the two Sides Supports (R) to the Housing Sides (M), between and flush with the ends of the Corner Supports (N), 2-3/4- inches from the exposed edges of the Housing Sides (M). Use 2”-long screws, spacing them about 6” apart.

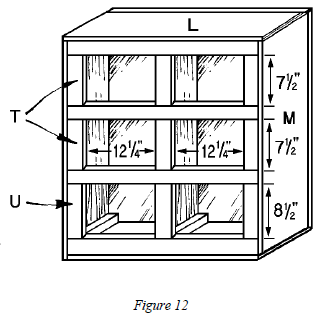

Adding the Rails and Stiles

1. The front of the drawer housing consists of rails (horizontal members) and stiles (vertical members). These are the finished front of the drawer housing and will accommodate the drawers. A diagram of the rails and stiles is shown in Figure 12. It is very important that each of the stiles

and rails are installed exactly square, or your drawers will not fit properly.

2. Cut four Rails (S) from 1 x 4 pine, each 35 inches long.

3. Cut six Upper Stiles (T) from 1 x 4 pine, each 7-1/2 inches long.

4. Cut three Lower Stiles (U) from 1 x 4 pine, 8-1/2 inches long.

5. Attach the four Rails (S) at the front of the completed housing. Pay particular attention to the spacing between the rails. The four upper openings must be exactly 7-1/2 x 12-1/49

inches, and the lower two openings must be exactly 8-1/2 x 12-1/4 inches, as shown in

Figure 12. All four of the Rails (S) fit inside the exposed edges of the Housing Sides (M)

and Top and Bottom (L). The rails cover the exposed edge of the center divider leaving a 2-

inch allowance at the front. Glue and screw them in place with 2”-long screws, screwing

through the Rails (S) into the 2 x 2 pine supports.

Making the Drawers

There are six drawers that fit into the drawer housing. Although the dimensions of the two

bottom drawers differ from those of the four top drawers, each drawer is constructed identically.

An assembly diagram is shown in Figure 13.

1. Rip 20 linear feet of 1 x 8 pine to 6-1/2 inches in width.

2. Cut the following pieces from the ripped pine (to construct one of the four upper drawers):

two Drawer Front/Back pieces (V), each 11-3/4 inches long; two Drawer Sides (W), each 16 inches long.

3. Cut a 1/4 x 1/4-inch dado 3/8-inch from the lower edge on the inside of each drawer piece

(V and W) to accommodate the plywood bottom. (For some helpful hints on cutting dadoes, refer to the section on “Tips and Techniques” on the home page.)

4. Cut one 11-1/4” x 16-1/2” Drawer Bottom piece (X) from 1/4-inch-thick plywood.

Assemble the drawer as shown in Figure 13 using glue and finishing nails. The decorative

drawer front will be added later.

5. Repeat steps 2 through 4 three more times to build the additional three upper drawers.

6. Cut the following pieces for one lower drawer from full-width 1 x 8 pine: two lower drawer

front/back pieces (Y), each 11-3/4 inches long, and two lower drawer sides (Z), each 16

inches long.

7. Cut a ¼” x ¼” dado 3/8 inch from the lower edge on the inside of each drawer piece (Y and

Z) to accommodate the plywood bottom.

8. Cut one 11-1/4” x 16-1/2” Drawer Bottom piece (AA) from 1/4-inch-thick plywood. Using

glue and 3-penny finishing nails assemble the drawer as shown in Figure 13.

9. Repeat Steps 6 through 8 to build the additional lower drawer.

Building the Drawer Fronts

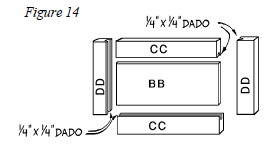

Although they have different dimensions, the upper drawer fronts and lower drawer fronts are constructed in exactly the same manner. Each drawer front is nothing more than a center panel of ¼”-thick plywood inserted into a 1 x 2 frame and trimmed with decorative molding (Figure 14). It’s not difficult to do, but it does require a certain amount of precision when cutting to obtain a professional-looking finished product. For the best results, don’t hurry the process, and be meticulous in your work.

1. To make one Upper Drawer Front, cut one 10-1/2” by 4-1/2” drawer panel (BB) from ¼”

thick plywood.

2. Cut two Top/Bottom frame pieces (CC) from 1 x 2 pine each 10-1/4 inches long.

3. Cut two Side Frame pieces (DD) from 1 x 2 pine each 5-1/2 inches long.

4. Cut a 1/4 x 1/4-inch dado along inside edges of each of the frame pieces (CC and DD) to

accommodate the drawer panel (BB), as shown in Figure 14.

5. Place the drawer panel (BB) into the dadoes cut in the frame pieces (CC and DD). Glue

and clamp, then nail the frame pieces together.

6. Measure and cut four pieces of ¼” cove molding to fit around the inside edges of the frame. Setting each piece of cove molding with the curved side up, miter both ends at a 45-degree angle. Attach the mitered pieces to the drawer frames (CC and DD) with the glue and wire brads.

7. Repeat Steps 1 through 6 three more times to assemble the remaining upper drawer fronts.

8. The two lower drawer fronts are identical with the upper ones, except that they are 1 inch

taller. To construct the two lower drawer fronts, repeat steps 1 through 6, but with the

following modifications: cut the lower drawer panel (BB2), 10-1/2 x 6-1/2 inches (from

1/4-inch-thick plywood); cut each of the two Lower Drawer-Front Side Frame pieces

(DD2), each 6-1/2 inches long, from 1 x 2 pine.

Installing the Hardware1. Follow the manufacturer's instructions to install the metal drawer glide between the Housing Back (O), and the Rails (S).

2. Install a roller on the bottom of each drawer, and on the inside of the Rail (S), again following the manufacturer's instructions.

Attaching the Drawer Fronts

1. For the job to look very professional, each drawer front must be exactly straight and level. Set the assembled drawers inside their respective drawer opening in the cabinet, placing them on the metal drawer glides.

2. Place a scrap piece of wood between the back of the drawer and the back of the drawer housing so that the drawer is held flush with the front of the rails and stiles. Begin with the top-most drawer fronts. Use heavy-duty double-sided tape to temporarily hold the drawer front in place on the drawer until you have all the drawer fronts positioned exactly right. Then remove the drawers one at a time and attach the drawer front to the drawer with two 1-1/4” screws driven from the inside of the drawer into the drawer front frame pieces.

3. Install drawer pulls on each of the drawers and on the cabinet doors.

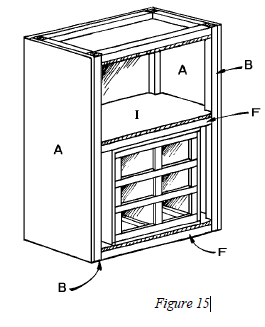

Attaching the Drawer Housing to the Armoire

1. Slide the completed drawer housing inside the lower section of the armoire. As shown in Figure 15, the exposed edges of the drawer housing should be flush with the exposed edges of the Inner Shelf (I), the Front Horizontal Supports (F), and the Bottom (H). The sides of the drawer housing should be positioned equidistant from the Vertical Supports (B) with 3-1/2 inches of open space on each side of the housing.

2. Using 2-1/4”-long screws, attach the drawer housing to the armoire, screwing through the top of the housing into the Front Horizontal Support (F). Similarly, screw through the housing bottom into the bottom (H) and into the front horizontal support (F) below thebottom (H). Refer to Figure 15.

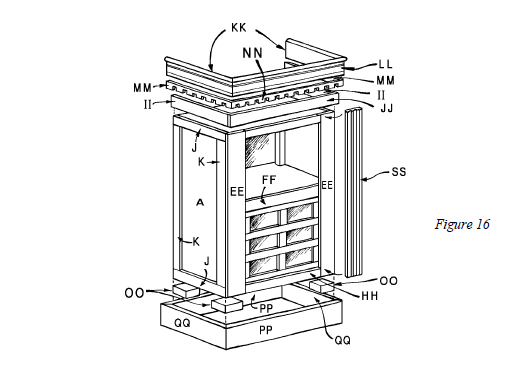

Adding the Front Trim

1. Cut two Vertical Front Trim pieces (EE) from 1 x 8 pine, each measuring 6 feet long.

2. Attach them on either side of the front of the armoire, over the edges of the Side Trim pieces (J and K), as shown in Figure 16.

3. Cut one 35-inch-long Shelf Trim piece (FF) from 1 x 4 pine.

4. Fit the Shelf Trim piece (FF) between the two Vertical Front Trim pieces (EE) so that it covers the exposed edge of the Inner Shelf (I) and the Front Horizontal Support (F) below, and the Top Housing (L). It should be absolutely flush with the top surface of the shelf. Glue and screw it in place using 2-1/4” screws.

5. Cut one Top Trim piece (GG) from 1 x 4 pine, 35 inches long. Rip it lengthwise so that it

measures 2-1/2-inches wide.

6. Fit the Top Trim piece (GG) between the two Vertical Front Trim pieces (EE) so that it covers the exposed edge of the Top (G) and the Front Horizontal Support (F) above the Top (G). Make sure that it is absolutely flush with the bottom surface of the Top (G). Glue and screw it in place using 2-1/4”-long screws.

7. Cut one Bottom Trim piece (HH) from 1 x 4 pine, 35 inches long. Rip it lengthwise so that

it measures 3 inches wide.

8. Fit the Bottom Trim piece (HH) between the two Vertical Front Trim pieces (EE) so that it

covers the exposed edge of the Bottom Housing (L), the Bottom (H), and the Front

Horizontal Support (F) below the Bottom (H). Glue and screw it in place.

Adding the Top Trim1. Cut two Top Side Trim pieces (II) from 1 x 4 pine, each 25-1/2 inches long.

2. Glue and screw the Top Side Trim pieces (II) to the top and sides of the armoire, as shown

in Figure 16, overlapping the Horizontal Side Trim pieces (J) by 1 inch. Use 2-1/4”-long

screws spaced about 8 inches apart to attach all of the trim pieces to the armoire.

3. Cut one Top Front Trim piece (JJ) from 1 x 4 pine, 51 inches long.

4. Glue and screw the Top Front Trim piece (JJ) to the top front of the armoire, as shown in

Figure 16, overlapping the Top Trim piece (GG) by 1 inch, and covering the exposed edges

of the two Top Side Trim pieces (II).

5. Cut two Side Molding pieces (KK) from 3-1/2-inch-wide decorative molding, each

measuring 26-3/4 inches.

6. Cut one Front Molding piece (LL) from 3-1/2-inch-wide decorative molding, 52-1/2 inches.

7. With each piece standing on edge, miter both ends of the Front Molding piece (LL) and one

end of each of the two Side Molding pieces (KK) at a 45-degree angle.

8. Glue and nail the three mitered molding pieces to the top of the armoire, as shown in Figure

16, overlapping the Top Front Trim (JJ) and the Top Side Trim (II) by 1 inch.

9. Cut two Side Box Trim pieces (MM) from box molding each 26-1/4 inches long.

10. Glue and nail the Side Box Trim pieces (MM) to the top sides of the armoire, just under the

Side Molding pieces (KK), as shown in Figure 16.

11. Cut one Front Box Trim piece (NN) from 1 x 4 pine, 52 inches long.

12. Glue and nail the Front Box Trim piece (NN) to the top front of the armoire, as shown in

Figure 16, just under the Front Molding piece (LL). The front box trim should cover the

exposed ends of the two side box trim pieces (MM).

Adding the BaseThe armoire is supported by a 2 x 8 base that is reinforced by blocks at all four corners. The

blocks are cut and attached to the armoire first.

1. Cut four Corner Blocks (00) from 2 x 8 pine, each 6 inches square.

2. Position them flush with the outermost corners of the bottom of the armoire. Then, using glue and 3-1/2”-long screws, screw through the blocks into the 2 x 2 horizontal supports and the 1 x 4 trim pieces at the bottom of the armoire, as shown in Figure 16.

3. Cut two Front and Back Base pieces (PP), each measuring 52-1/2 inches.

4. Stand each front/back base piece (PP) on edge, and miter the ends at a 45-degree angle, and

glue and screw them in place, overlapping the bottom of the armoire by 1 inch. Screw them

securely both to the bottom of the armoire and to the corner blocks.

5. Cut two Side Base pieces (QQ) from 2 x 8 pine each measuring 26-1/4 inches.

6. Standing the side base pieces (QQ) on edge, miter each end at a 45-degree angle. Glue and

screw the side base pieces (QQ) in place, overlapping the bottom of the armoire by 1 inch,

and matching the miters on the Front and Back Base pieces (PP). Screw them securely to Figure 16

the bottom of the armoire and to the Corner Blocks (OO). Use 3-1/2-inch-long screws to screw into the Corner Blocks (OO).

7. Use 3-1/2-inch-long screws to screw the two Side Base pieces (QQ) and the two Front and

Back Base pieces (PP) together, placing two screws on each side of each corner.

Adding the Doors

Before adding the doors, double-check the measurements of your opening. When placed sideby-

side, the finished doors (with outer corner molding added) should be 1/2-inch larger than the

opening on all four sides.

1. Cut two Door pieces (RR) from 3/4-inch-thick plywood, each measuring 17-1/2 x 66 inches.

2. Trim all four sides of the Door pieces (RR) with outer corner molding. Be sure to miter the

molding at a 45-degree angle on each corner. Attach the molding to the doors with glue

and wire brads, countersinking the brads.

3. The easiest method to hang the doors (RR) is to lay the armoire on its back. Then you will

not be supporting the weight of the doors while you attempt to hang them. Place the doors

over the opening so that they meet in the center of the opening. Place the hinges

underneath the doors, spacing them the same distance from the top and bottom of the doors,

and in the center of the doors.

4. Follow the manufacturer’s directions to attach the hinges to the doors and to the armoire.

Installing the Fluted Trim

1. Measure your completed armoire to be certain before cutting the fluted trim for the front

sides of the armoire, as the trim should be cut exactly to fit. Then cut two Fluted Trim

pieces (SS) from 3-1/2” fluted molding each 70 inches long (plus or minus depending upon

your measurements.)

2. Attach the Fluted Trim pieces (SS) to the front sides of the armoire, directly over the two

Vertical Front Trim pieces (EE), as shown in Figure 16. Attach them with glue and small

finishing nails, countersinking the nails.

3. Follow the manufacturer's directions to attach the hinges to the doors and to the armoire.

4. Attach the door handles to the center of the doors, following the manufacturer's directions.

Finishing the

Armoire Two door Woodworking

1. If you plan to house a television set or other electronic equipment in the top of your completed armoire, you need to cut a small hole through the back of the armoire. It should be positioned at the center back, flush with the shelf top, and should be no larger than is required to accommodate a plug.

2. Fill any nail or screw holes with wood filler.

3. Sand all surfaces thoroughly.

4. Paint or stain the completed armoire the color of your choice.

5. Take an admiring look at your handiwork. It was a lot of effort and time, but what an

accomplishment for you! thank you for reading DIY step by step

Armoire Two door Plans Woodworking